China’s economic growth since the turn of the century has been accompanied by efforts to improve energy efficiency, leading it to become “the world heavyweight” in this area, according to the International Energy Agency (IEA).

Energy efficiency improved by 30% in China between 2000 and 2015. Industry was both the main driver of economic growth and the biggest consumer of energy during this period but recorded the largest improvements in efficiency. Brazil’s economy also recorded high annual growth rates over the same period until it entered recession in 2014. Yet, energy efficiency in Brazil has not improved.

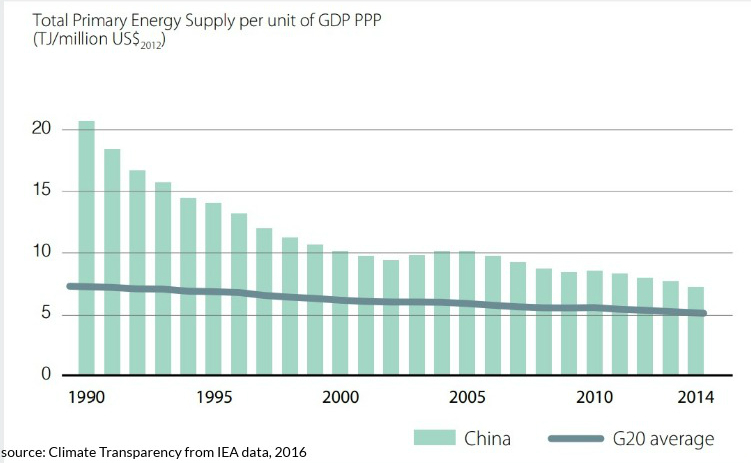

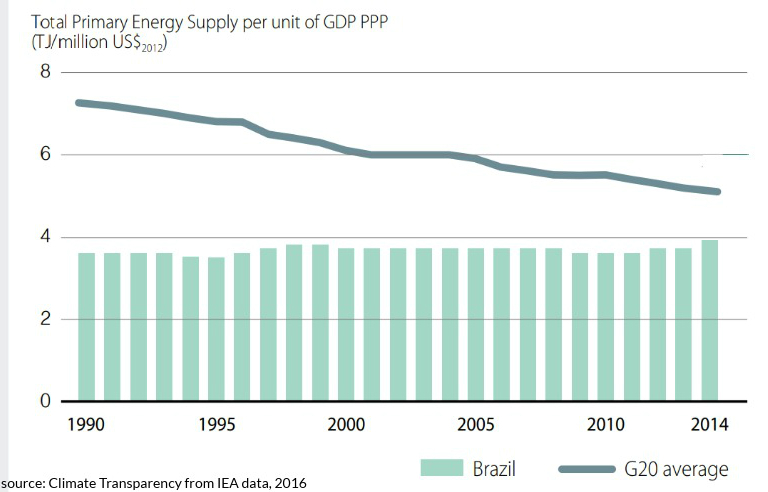

Economies tend to use more energy as they grow. However, reducing energy intensity – calculated as the amount of energy used per million US dollars of gross domestic product (GDP) generated – can lead to an eventual decoupling of energy consumption from economic growth.

In Brazil, the energy intensity of the economy has remained conspicuously unchanged since 1990, when the country used less than four terajoules of energy per US$1 million of GDP.

The research group Climate Transparency rates Brazil’s recent developments (2009-2014) as “very poor”. In contrast, China has witnessed steady improvements in its energy intensity, with recent performance rated as “very good”. These improvements are linked to centrally planned programmes designed to optimise the country's energy efficiency that were first launched in the 1990s.

Almost 30 years ago, China required over 20 terajoules/US$1 million GDP. Today, the figure stands at around a third of that 1990 high.

The energy intensity of Brazil’s economy (1990-2014)

Why have these “emerging economies” had such different experiences of balancing energy efficiency with growth? A closer examination of consumption patterns in both countries, and the policies that influence them, hold important clues.

Industry is key

Industry in China accounts for around 70% of total end-user energy consumption, which makes the sector critical to China's efforts to reduce carbon emissions because 85% of its energy use is derived from non-renewable sources.

As in many developing nations, combining measures to save energy and boost efficiency has been a challenge for China. In the 1980s, when energy use was particularly high in the steel, oil-refining, coking and chemical sectors, the government started building a system to improve efficiency.

Both the IEA and China’s top planning body the National Development and Reform Commission (NDRC), estimate that between 1990 and 2013 the G20 nations, which account for 80% of primary energy consumption worldwide, saw energy intensity drop by around 1.5% a year, collectively.

In Brazil, industry is followed closely by residential consumers, which represent 28% (2016) of total energy consumption, according to the 2017 Statistical Annual of Electrical Energy, published by Brazil’s Energy Research Company’s (EPE), the government’s planning and research arm. Most energy saving initiatives have tended to focus on domestic consumption.

After more than two years of recession that led to an aggregate 8% contraction of the economy, Brazil's economy is now growing again, albeit slowly. Greater energy consumption looks likely to follow, especially in the industrial south-east (which accounted for the largest regional drop in energy use during the downturn). Nationally, energy consumption grew 1.3% in 2017; following decreases in 2015 and 2016 of 6.2% and 2.5% respectively.

But as its economy recovers, Brazil could look to China as an example for how to deliver improvements in energy efficiency, according to Dai Yande, head of the NDRC’s Energy Research Institute (ERI).

While there are lessons in China’s success, many of these are closely linked to the country’s unique political and governance systems. Applied to an ambitious programme of industrial upgrading, which prioritised the development of higher value-added sectors and shifted investment away from energy-intensive heavy industries, it reveals where gains in energy efficiency can be achieved.

The third stage: from 'managing' to 'promoting'

China’s system for reducing energy intensity has gone through two stages, and is currently shifting to a third, according to ERI.

The first stage was from 1981 to 1997. At the beginning of this period, China produced only one-seventh of the energy it does today. Government energy saving campaigns were intended to relieve energy shortages by planning all aspects of energy-saving in businesses.

This period saw the establishment of mechanisms for assigning and auditing energy quotas for state-owned companies, the main consumers of energy at that time. These were driven by government orders that placed strict limits on energy use by businesses. Energy use was brought under control, and reduced where possible.

The second phase started in 1997 when the Energy Conservation Law came into effect. This made the state responsible for setting energy efficiency standards. New companies were required to satisfy the standards before starting operations.

The government no longer only ordered state-owned firms to take certain energy-saving steps – all types of companies were legally required to save energy. The Central Committee, the Chinese Communist Party’s top leadership body, approved the conservation of resources as part of national policy.

The Administrative Measures for Energy Conservation in Key Energy Consumers, which were issued in 1999, provided more detailed rules to firms using more than the equivalent of 10,000 tonnes of coal for energy per year.

Companies hired “energy managers”, responsible for overseeing energy use. Only engineers with three years of experience in energy-saving work were qualified to hold the position.

The government also started to offer substantial subsidies to encourage energy-saving measures, such as the purchase of better equipment and technology. By this point, a sound system for managing energy-saving in some Chinese companies had begun to take shape.

The third, most recent phase of energy saving arrived with the new environmental focus of the 11thand 12th Five-Year Plans (FYP) for development that covered the periods of 2006-2011 and 20011-2015, respectively.

The 13th FYP period beginning 2016 continues the legacy with a special Action Plan for Energy Conservation jointly issued by 12 ministries including NDRC, the Ministry of Industry and Information Technology (MIIT), the Ministry of Science and Technology (MOST), and the Ministry of Finance (MOF).

Toughening targets

As China’s energy-saving strategy intensified, its national energy consumption targets grew steadily more ambitious.

In 2006, a target was set to reduce energy intensity by 20% over the period of the 11th FYP. This stressed the need for a more sustainable model of development. It was the first time China had set a binding energy-intensity reduction target in its national quinquennial plan and marked the start of energy-intensity controls.

Wei Han, program officer on industry at the Energy Foundation China, said that industry insiders regarded the target as a powerful signal from government promoting energy saving and emissions reductions, mitigating climate change and promoting green economic growth. The target translated into an estimated annual emissions reduction of over 1.5 billion tonnes of carbon dioxide.

But it also attracted controversy.

In a desperate late rush to meet the targets, local authorities reportedly cut power supplies to factories, traffic lights, and even hospitals. The episode also served to demonstrate how responsibility for targets was increasingly held by local officials that were accountable for their performance. In the end, China achieved an energy intensity reduction over the 11th FYP of less than one percentage point shy of the goal.

Under conditions of rapid economic growth an energy intensity target may not prevent growth in overall energy consumption. To achieve this, the Chinese government added a total energy consumption target in 2016 to existing intensity targets, saying that “2020 total energy consumption will be within 5 billion tonnes of coal equivalent.”

In desperate late rush to meet the targets, local authorities reportedly cut power supplies to factories, traffic lights – even hospitals.

However, some industry figures claimed the target was not radical enough. Nonetheless, the ceiling on total energy consumption became a major factor in local government decision-making, encouraging further efforts to develop sectors such as high-technology that produce more economic output for less energy input.

The energy police

For “hard limits” to be more than empty words, strong enforcement is needed. Alongside internal company employees with responsibility for energy-saving, the government also set up a system for oversight of energy-saving, with provincial county and city governments gaining energy efficiency oversight bodies and teams.

Over the 11th and 12th Five Year Plan periods a number of measures and programmes were put in place, explained Wei Han. These included closing small, inefficient plants; creating the Top 1,000 Enterprises Program for industrial energy efficiency to foster technological upgrades in large enterprises; and establishing the Ten Key Energy Conservation Projects initiative, to deploy technologies such as low-carbon lighting and combined heat and power (cogeneration).

Today, officials are responsible for checking on the energy-saving performance of companies, looking for out-of-date equipment that should be replaced, and seeing whether quotas have been met.

The industry view is that the system promotes energy-saving, environmental protection and green development strategies, and thereby accelerates the upgrading and high-quality development of the sector.

It is also a means of developing China’s domestic energy-saving and environmental-protection technologies sector.

The key role of subsidies

During the 11th FYP period China invested a total of 846.6 billion yuan (US$135 billion) in energy-savings and emissions-reductions.

Government subsidies have been key to promoting energy efficiency, as 149.7 yuan (US$23.7 billion) of the total investment came from central government. Investment more than doubled during the 12th FYP to over 2,000 billion yuan (US$317 billion), with central government's commitment approaching 220 billion yuan (US$34 billion), primarily in the form of subsidies for energy-saving measures.

In Shanghai, for example, industrial firms in 2017 received 600 yuan (US$95) in subsidies for every tonne of coal equivalent saved per year (up to five million yuan, and up to 30% of total project cost). Strong financial subsidies from different levels of government played a key role as “seed capital” in ensuring the energy-saving targets set in the 11th and 12th FYPs were met.

The Ministry of Finance and NDRC also ran comprehensive trials of energy-saving and emissions-reduction policies in 30 trial cities. These were given annual funding of between 400 and 600 million yuan (US$65-95 million) over a three-year period to fund innovation in low-carbon industries, clean transportation, green buildings and renewable energy.

Brazil: Few incentives to save

In 2001, the Brazilian government imposed a period of electricity rationing as the hydropower-dependent nation experienced a severe drought. The experience helped put energy efficiency on the national agenda. Brazilians had been accustomed to an abundance of energy but were forced to reduce consumption and eliminate waste. Until this time, efficiency concerns in industry had been closely linked to economic cost-benefit ratios, with companies weighing-up the level of investment needed in order to reduce consumption through inefficiency.

José Antônio Sorge, of energy company Ágora Energia believes that the lack of financing is a barrier to greater efficiency in Brazilian industry. The main source of credit for Brazilian companies is national development bank the National Social and Economic Development Bank (BNDES). “It is difficult to find sources of funding,” he said.

BNDES has a line of financing for renewable and energy efficiency projects called Green Energy. These projects received resources amounting to R$8.2 billion (US$2.5 billion) in 2017. However, aside from BNDES there are no other lines of credit.

The lack of financing options means many projects fail to make it off the drawing board, Sorge said. He added that diagnostic work to identify where energy is wasted and what actions are necessary to make improvements is insufficient.

According to André Lucena, professor of energy planning at the Federal University of Rio de Janeiro (COPPE-UFRJ), entrepreneurs considering capital opportunity costs (the cost of choosing to invest in some areas and forgoing others) and financing conditions, would find few incentives to save energy.

Greenpeace Brasil agrees. The cost of replacing inefficient technologies and the lack of knowledge among businesses of the long-term benefits this can bring are significant, the organisation wrote in a 2016 report entitled Energy [R]evolution.

The report calls for energy efficiency auctions, the progressive elimination of obsolete technologies and more rigorous and binding standards for rational energy use by industry. Measures, such as the incorporation of energy-efficient elements into the Brazilian civil construction code, for example, would also be welcome in this context, said Lucena.

A recent EPE study recognises the need for quicker movement towards rational energy use:

“There are still barriers that hinder the spread of energy efficiency, such as the low prioritisation of efficiency projects by companies and consumers, a lack of knowledge about efficiency potential and measures, a shortage of information and data, a lack of confidence on the real costs and benefits of efficiency actions, business models for making investments in efficiency, and resistance to change”.

Implementation in China

In China, some regions implemented policies on differentiated, punitive or tiered pricing of electricity. Energy-hungry firms failing to meet minimum standards paid punitive prices for their power, while tiered pricing was imposed on concrete and aluminium manufacturers, meaning costs went up as more power was used.

Benxi Steel Industries, Liaoning province, northeast China (image: Andreas Habich)

Benxi Steel Industries, Liaoning province, northeast China (image: Andreas Habich)

Wei Han said that the combined pressure from central and local government meant that more firms became subject to tougher policies. These efforts were the biggest worldwide, and the targets the most ambitious, she said.

Under this system, the government could decide what energy-saving technology to promote and what degree of subsidy support to provide. Interested firms could apply for the subsidy and, on approval, make the changes. The government would then check the implementation and disburse the subsidy.

This method – characterised by government intervention and high subsidies – started to change in 2013 when the Central Committee decided at a plenary conference to “accelerate transformation of the government’s functions”. In practice this meant limiting government micro-management and exercising powers in a standardised and efficient manner.

With the government stepping back, market mechanisms are expected to gradually come to the fore and drive China’s industrial energy-saving reforms.

The limitations of Chinese-style energy-saving

The Chinese government has given strong indications of its support for energy saving since the 1980s. Sorge believes strong public policies are equally critical in Brazil. He compares energy efficiency with microgeneration, especially rooftop solar panels, which has grown quickly in Brazil in recent years, mostly in homes, but increasingly in small industries and businesses thanks to the introduction of regulations incentivising installation in 2012 by the National Electrical Energy Agency (ANEEL).

But the level of support provided by the Chinese government also has drawbacks. Some warn the funding has supported energy-saving improvements for a number of steel, concrete and aluminium firms – but these are sectors where competition is fierce and government subsidies will undermine the role of market competition.

These policies can also be expensive to implement, as can oversight. For example, the government requires companies receiving subsidies to undergo third party audits. Yet, during implementation local and provincial officials already carry out check-ups, as do the national energy-saving and financial authorities, and the National Audit Office. Some companies have complained of being audited or inspected as many as seven times.

Replicable success?

China’s energy-saving campaign has taken different routes to those promoting renewable energy and electric vehicles (or EVs), but the results have been the same. China’s top-down governance, government intervention in the economy and ability to pay out high subsidies have laid the foundations for a number of low-carbon transformations which have drawn worldwide attention.

As these sectors rapidly expand, the government’s approvals and inspections processes, along with the expensive subsidies, become hard to sustain. After initial strides forward, recent years have seen the government cut various subsidies, and as industrial energy efficiency improves, continued reductions in industrial energy consumption will become increasingly difficult.

Although China’s gains may become increasingly marginal, other developing economies should take note, since they form part of an economy-wide transition that challenges industry by raising the costs of energy inefficiency, and striving to upgrade to higher value-added, and in many cases less polluting sectors.

The early stages of Chinese industrial energy efficiency programmes may have picked the low-hanging fruit, but this still required strong stimulus and oversight from the government, which then became a decisive factor in industries’ thinking about energy consumption and waste.

As the policies evolved to incorporate market mechanisms, they also promoted the idea that less energy-intensive industries might bring new benefits and opportunities.

If Brazil is to tread a few steps along the latter stages of China’s path, it must create the conditions for old, new and prospective industries to take on the energy efficiency challenge. In doing so, they will be encouraged to change the outmoded perception that investment in energy efficiency is not a price worth paying.