If the cement industry were a country, it would be the fourth largest CO2 emitter, accounting for 7% of global emissions – about the same share as India.

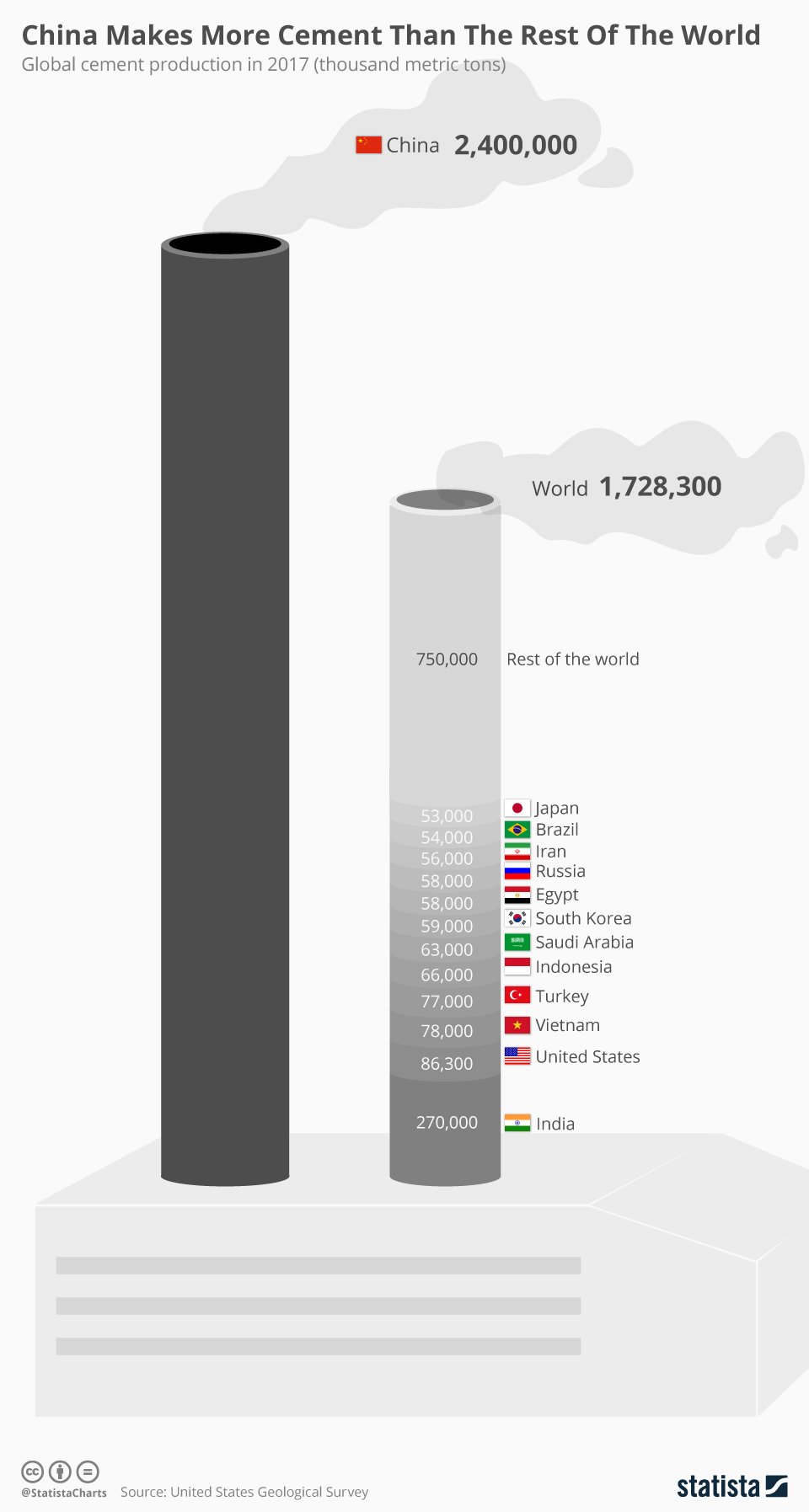

China produces the majority of the world’s cement, a powdery substance that is mixed with sand, gravel and water to make concrete. In the period 2011-2013, China produced more cement than the US in the entire 20th century.

The Chinese cement industry has already made improvements in energy efficiency. In 2017, it accounted for 57% of the global industry’s output but only 52% of its emissions. However, emissions reductions from energy efficiency measures are tiny compared to those that could be achieved with innovative technologies such as carbon capture and storage (CCS), which sequesters emissions.

“Looking longer term, either we need to have carbon capture and storage for the cement industry, or we need to be looking at alternative materials,” said Madeleine Rawlins of the engineering consultancy Mott MacDonald, in an interview with China Dialogue earlier this year.

Unfortunately, most CCS technologies are still at an early stage of development. And with global cement production estimated to increase from four billion tons today to almost five billion in 2030, other methods to reduce emissions are urgently needed.

The problem with cement

Fundamentally, the problem with reducing emissions from the cement industry is the chemistry itself. To produce clinker – the key ingredient in cement – you need lime (CaO). The most common way of getting it is through a process known as calcination, in which limestone (CaCO3) is heated to around 1400C in a cement kiln breaking it down into lime. This releases a large amount of CO2 and accounts for around 50% of the total emissions from cement production.

One way to reduce emissions from calcination is to reduce the proportion of clinker in cement by substituting it with other materials, but these “novel cements” have not yet achieved large-scale commercial use.

About 40% of emissions have traditionally come from burning fossil fuels to heat kilns (with the final 5-10% accounted for by operations and transport). This means there is significant scope to reduce overall cement emissions by finding alternative fuels. In Europe, the use of natural gas, biomass and waste-derived fuels in cement-making has increased to about 43%, but in China the proportion is still only around 8%.

The type of alternative fuel used is important, as was seen recently when the EU labelled the use of palm oil in biofuels unsustainable due to deforestation concerns. In this context, burning waste sounds like a great option. Instead of it ending up in landfill, emitting methane and potentially reaching the ocean, waste becomes a valuable resource to reduce cement industry emissions.

A cement plant in Shaanxi province, 2018 (Image: Alamy)

Waste-to-energy

Producing one ton of cement emits a staggering one ton of CO2. To heat a cement kiln with waste requires about three times as much waste as coal, and can reduce emissions by around 10%, according to engineering company FLSmidth.

This is not revolutionary, but when combined with better waste management, the benefits of using waste in cement production are not negligible either.

Given that China’s municipal solid waste is set to grow at a rate of 8-10% each year, increasing the amount of waste used in cement-making should be of interest to Chinese policymakers. According to Jennifer Turner from the Wilson Center’s China Environment Forum, waste is the new front in China’s “war on pollution”, putting pressure on cities to improve waste management systems.

“China is seeking solutions to its municipal waste problem, so I think it’s quite likely that at some point as they’re reforming, more of China’s waste incineration could go to the cement sector,” says Turner.

The largest cement producers in China have already started developing “co-processing” technologies that bring coal alternatives into the production fuel mix. China Resources Cement (CRC) operates several such projects in the south of China, and China Conch Ventures has signed agreements with both China National Building Material and China Shanshui Cement to develop technologies that allow solid waste to be used.

However, many of these projects focus on industrial rather than municipal waste. Household waste has a higher moisture content and consequently does not burn as well as dry waste such as plastics. Given that wet and dry wastes are often mixed together in Chinese cities, the combustion potential of the latter cannot be fully exploited. Hence, waste-to-energy in the Chinese cement industry would benefit from cities improving their waste-management practices.

Managing household waste

Despite China’s waste-management issues, some companies have taken on the challenge and developed co-processing technology that can manage a higher moisture content.

According to Gao Changming, one of the key designers of the latest co-processing technology to handle household waste in the Chinese cement industry, China currently has 120 cement kilns for co-processing. Of these, only 53 are able to co-process household waste, and they are currently handling 5.2 million tons per year – only about 2.5% of China’s total municipal solid waste.

Asked whether current government policy is encouraging cement producers to adopt co-processing technologies, Gao emphasises the importance of waste-management systems such as the one introduced in Shanghai in July.

“Improved waste-management systems can reduce the costs associated with the pre-treatment of household waste for use in cement kilns. So if waste management were to be further developed it would greatly benefit cement plants using co-processing technologies,” says Gao.

Whether trying to deal with household waste or reduce emissions from the cement industry, the most effective way to mitigate damage to the environment and health will always be to “reduce” rather than “reuse”. In this case, to reduce our production of waste and concrete.

In the meantime, the development of co-processing technologies in the cement industry could help China reduce its dependence on coal while dealing with its mountain of waste.